Our many years of experience lie in the processing of thermosets. Whether dough polyester (BMC and SMC) or pourable – with us you have a competent partner at your side. We offer support from product development to series production. To offer a complete solution, we also have thermoplastic production. This enables us to process almost all plastics – a solution from a single source!

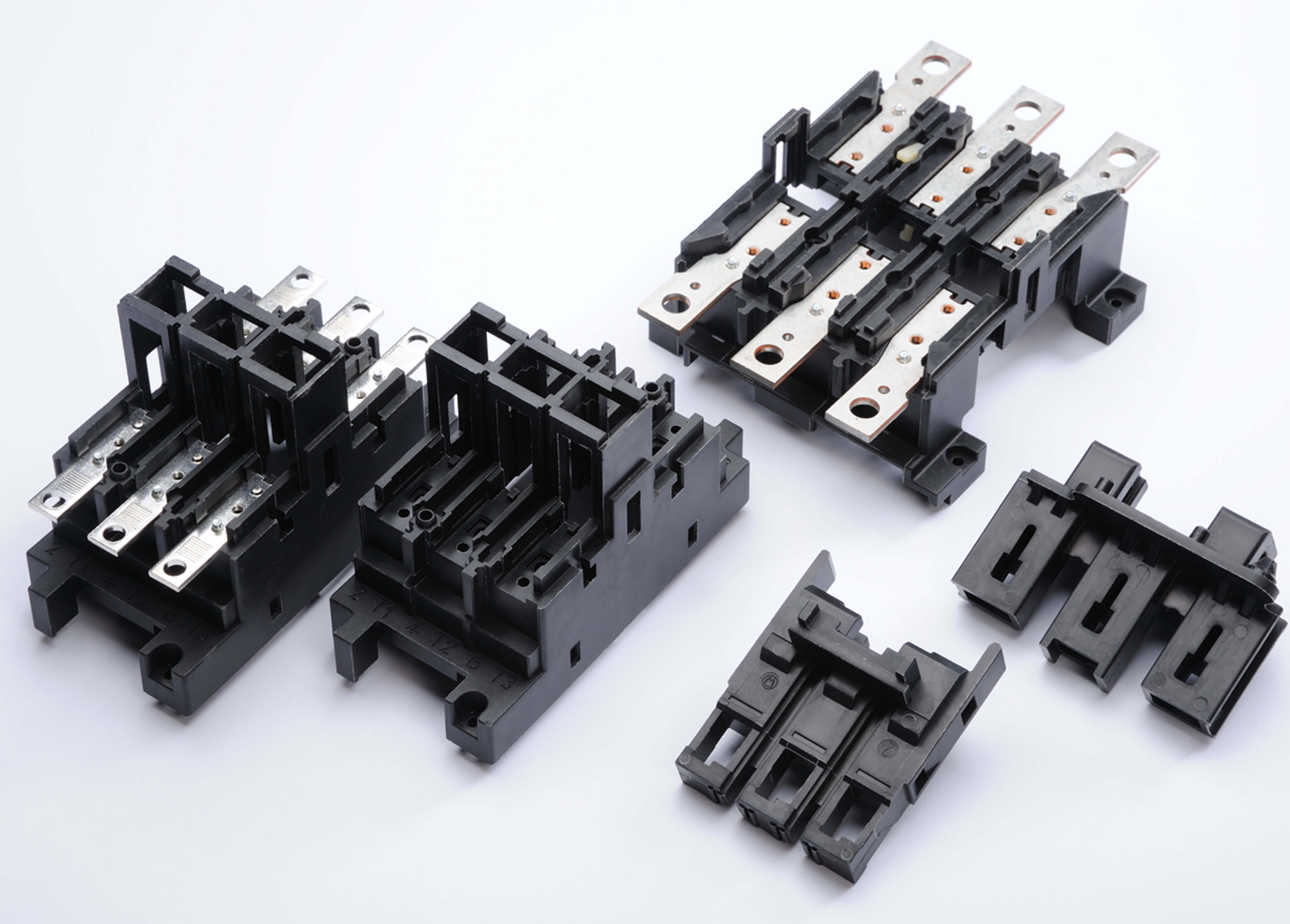

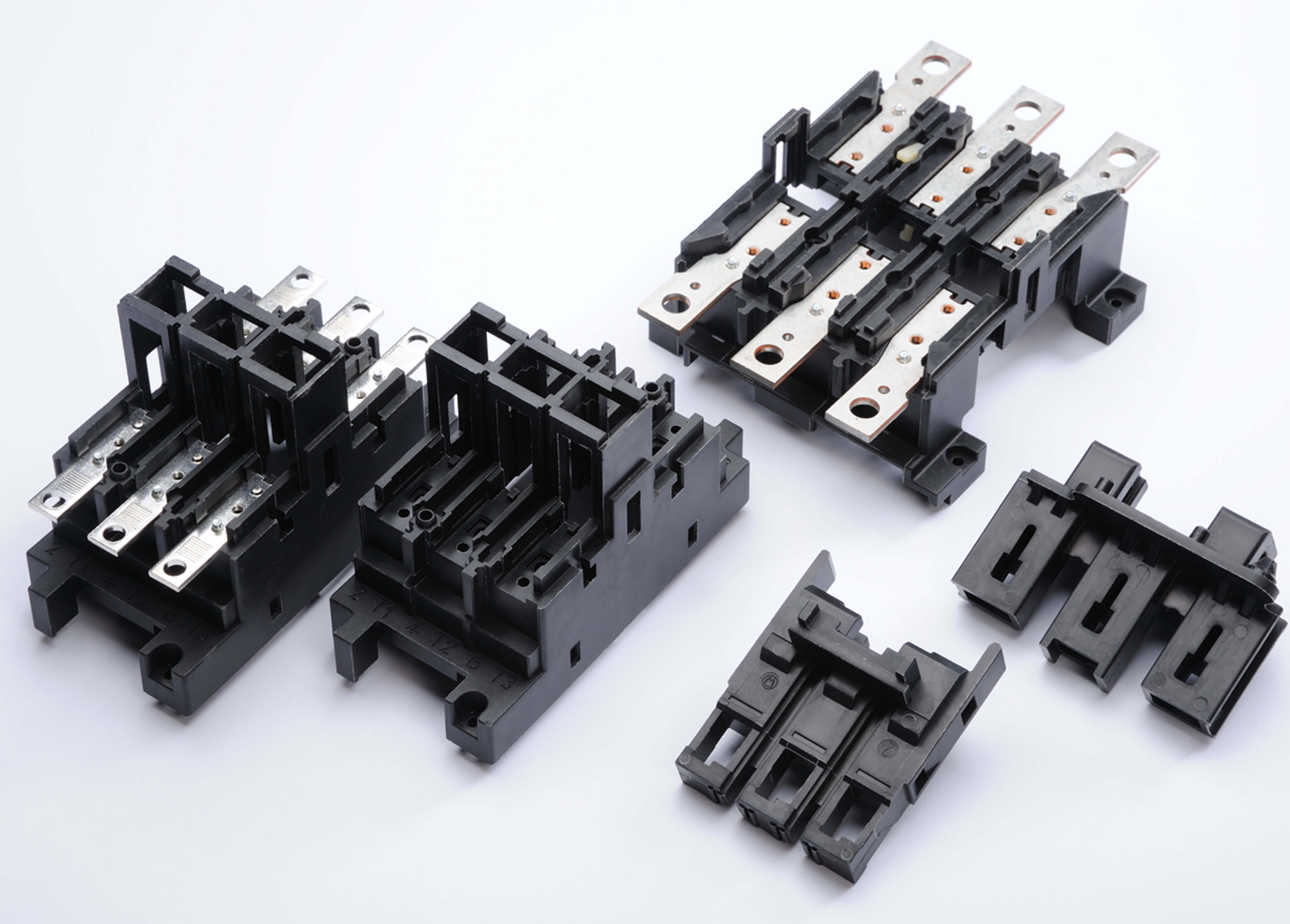

As part of a complete customer service, we are also able to carry out component assembly in addition to the production of plastic parts. This means you get a complete solution – from the injection-molded blank to the fully assembled product!

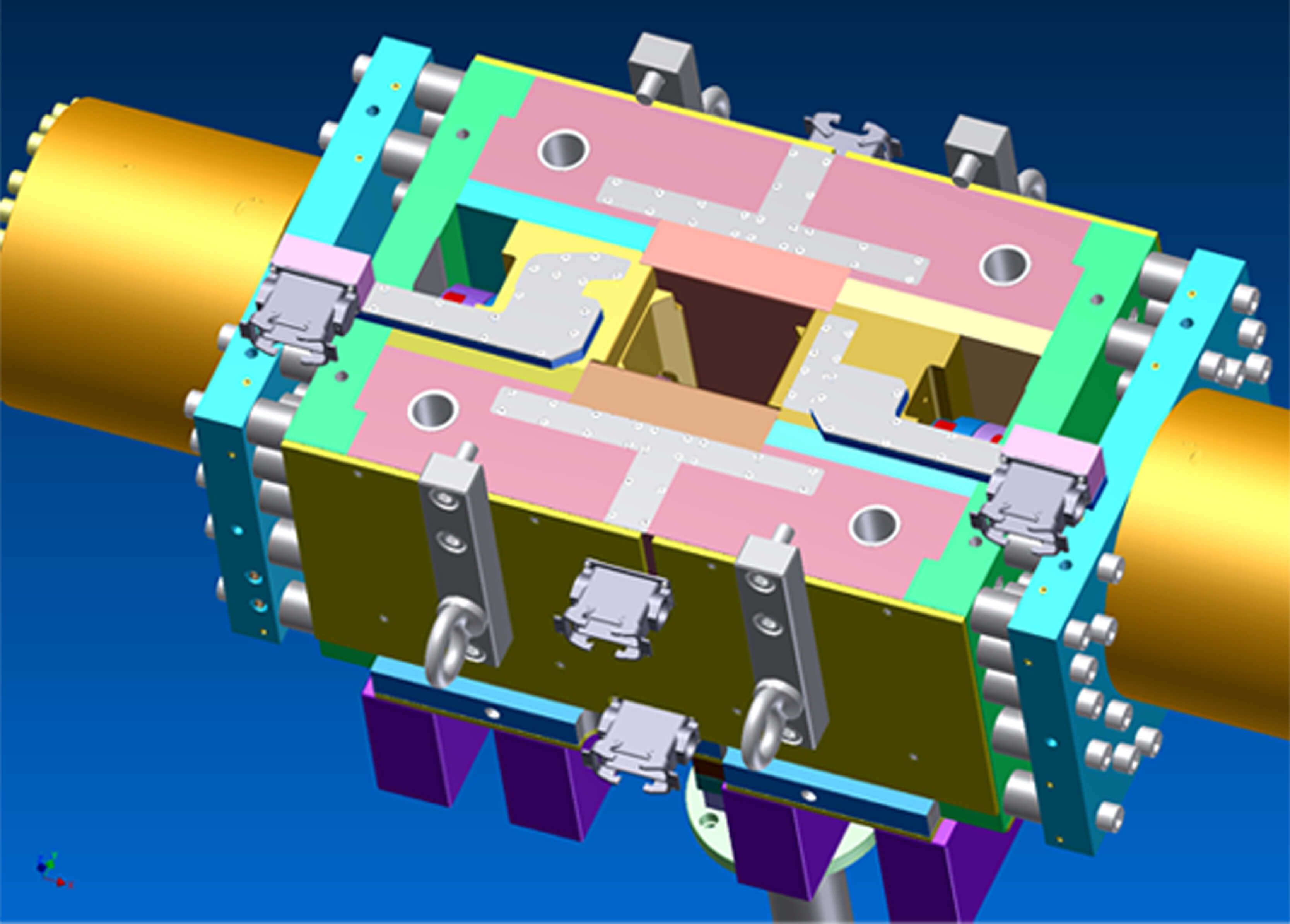

The first milestones for the new tool are set in our design department. We are always in close consultation with our customers. This results in a well-thought-out tool that meets all technical requirements.

In our production, a modern machine park from 30 to 160 tons on 2,500 m² is available. Together with our partners, we offer machines up to 800 tons pressing force. This enables us to offer you highly productive and cost-effective manufacturing. Zero-error tolerance and the highest quality are always our top priorities and are constantly monitored by our quality team.

One of our core competences is mold making with our in-house design department. This allows us to develop individual tools. Whether large or small series – from the first draft to production and delivery – we professionally implement your project, including tool creation, modification, or repair in both thermoplastics and thermosets.

The continuous improvement and optimization of internal processes to achieve the required quality standard is a central element of our daily activities.

Our ISO 9001:2015 certification proves that our production meets the highest technological requirements.